News & Press

Extracting and modifying xylans for personal care, cosmetics and nutraceutical applications

01 February 2022

EnXylaScope aims to develop environment friendly xylan extraction process from forest and agriculture biomass and thereafter modify the xylan using enzymes to make it suitable to be used as key ingredient in an array of consumer products. The extraction activities target producing xylan with high molecular weight and with less substituents. Xylan modification activities use a tool of enzymes to modify the xylan. A set of product and feedstock specific cocktail of enzymes will be designed using experiment design and machine learning tools. The algorithms developed in this work package will be able to predict the enzyme cocktails based on the xylan composition and product requirement. Once the process benchmark is established using commercial enzymes, the enzymes produced in Enxylascope will be used for xylans modification. Severeal types of xylans will be generated by removing the substituents on xylan and grafting various types of functional groups on to the xylan backbone. The modified xylans will be tested for their chemical and physical properties including biodegradability as part of this work package, while application testing of the extracted xylans and modified xylans will be performed as part of another work package.

Xylan is the second most abundant plant polysaccharide, but its applications so far are mainly limited to production of pentose sugars which can be used for chemicals production and for production of prebiotics. While, cellulose has gained significant attention as a polymer due to its several unique properties among which crystalline nature and insolubility in water are highly important. In contrary, xylan is amorphous in nature, water soluble and heterogenous polymer. In addition to that, the composition of xylan varies significantly based on the feedstock type and this is due to the differences in substitutions on xylan backbone. Removal of substitutions from the xylan backbone not only decreases the water solubility, but also changes the physical and chemical properties of polymer, such as crystallinity.

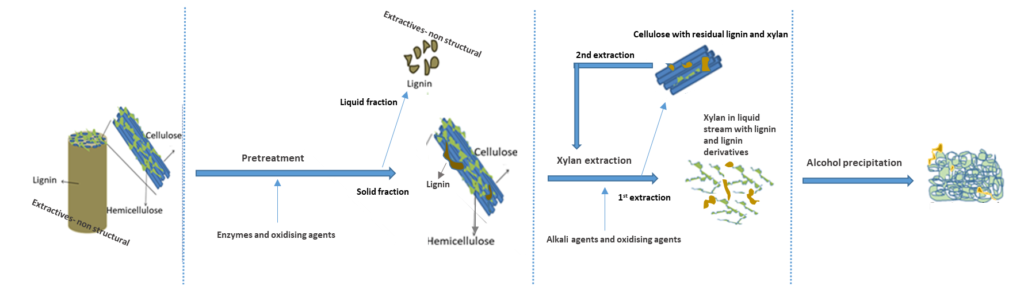

Chemical modifications of the xylan are well reported, but these modifications are done on native xylan (branched) and the chemicals used are either toxic or flammable. In contrary, enzymatic modification of xylan uses very mild conditions and both substituted and unsubstituted xylans can be modified using enzymes. Enzymatically modified xylans can be used in a broad range of applications such as personal care, cosmetics and nutraceutical. But, as xylan never gained enough attention as biopolymer, there are no commercial enzymes or processes available for enzymatic modification of xylan. EnXylaScope is going to change the perception on xylan by unravelling its potential as a biopolymer and its amiability for modification using enzymes and mild chemical reactions. Celignis’s approach that is being used in EnXylaScope project for xylan extraction is given in the figure below.

The extracted xylan is made water insoluble by following either of the three approaches 1. Removal of substitutions; 2. Cross-linking; 3. Grafting hydrophobic functional groups. All the three can be achieved by using enzymes. The enzymes for cross-linking and grafting are available commercially, while enzymes for removal of xylan side chains are available only in research scale volumes (ml). Celignis is currently testing the research grade enzymes to benchmark the process and to provide data for machine learning tools development.

As enzymes are the key players and xylan consists of a variety of substitutions, a suitable set of enzyme cocktails will be needed to achieve the desired project range. In order to achieve this in a conventional way, thousands of experiments will be needed and this will have a heavy impact on the timelines and cost of the product development. The cost and optimisation timelines are reduced in the EnXylaScope project with the help of intelligent experiment design algorithms developed by divis, one of the partners in the project. We will also use machine learning tools and graphic user interface (GUI) designed by divis to predict optimum set of enzymes based on the xylan type and the desired product.

EnXylaScope is within its first year and the following tasks are ongoing:

- Extraction of xylan from three different biomass types (wood, grass and cereals): Good progress has been made in extracting high quality technical grade xylans from poplar and wheat straw. Around 110 conditions are tested so far to produce various types of xylans with different molecular weights and different chemical compositions

- Characterisation of xylans obtained from various biomass types under various conditions: Xylans are characterised for chemical constituents and molecular weights. The selected group of xylans are tested for viscosity, emulsification ability and film forming properties

- Debranching the xylans using research grade enzymes and studying the properties of modified xylans: The enzymes sourced from Megazyme, Sigma and Creative enzymes are used for debranching poplar and wheat xylans. Modified xylans exhibited better emulsification abilities. Based on the preliminary data provided divis has developed experimental design which is optimised from >1000 experiments to around 120 experiments.

- Cross-linking the xylans with the use of commercially available enzymes: MetZyme® Laccases from MetGen are used for cross-linking xylans from wheat straw. The preliminary results have shown that these laccases have the ability to cross-link xylans in the presence of phenolic groups.

Enxylascope in the future will use the enzymes discovered and produced in Enxylascope for the modification of extracted xylans and use of MetGen enzymes for grafting hydrophobic functional groups on to xylan. Machine learning tools and GUI interfaces will be developed to predict the required enzymes and designing the most efficient enzyme cocktail. Seppic will work on extracted xylans for chemical modifications which will be compared with enzymatically modified ones. Biodegradability of both enzymatically and chemically modified xylans will be tested.